Thresh Factory of Christmas Toys

Today there will be an industrial report from the series Beauty and the Beast.

When you take out a bright ball from a beautiful package that you then hang on a Christmas tree, you probably do not even think about where and how it was made.

Yes, the bulk of Christmas toys now comes from China, but still not all.

There are four enterprises in Ukraine that produce good old glass Christmas toys, and it is quite possible that some of the balls on your Christmas tree are made on one of them. For example, in a completely old-school factory, which is located near Kiev.

It is hard to believe that such colorful balls can be produced in such an entourage, trashy place. It is also difficult to believe that every balloon is blown out by women workers at the expense of health, because the production of Christmas toys is incredibly harmful.

So, welcome to the place where the real soviet trash and the magic of the holiday loved by millions of people are miraculously combined - at the Klavdievsky Christmas tree factory.

The Klavdievsky factory has been operating since the distant 1949 and today it is slowly getting out of the long-term crisis caused by the collapse of the USSR.

I can imagine how difficult it is for an enterprise operating only 2 months a year to survive in the face of massive expansion of cheap Chinese consumer goods.

This is probably why I don’t want to paint this reportage in critical colors, but just to talk about how ordinary people in the old Soviet factory make beauty for the main holiday of the year.

The factory has four workshops, which are located in different buildings.

It all starts with a glassblower, which is located in this old two-story building with fun colorful pipes.

The factory has found a great way to increase profits in addition to the main activity - the production of toys. It allows you to look at how it is done for money. And this is a huge respect! I really like to do industrial reporting, and usually you need to make some efforts in order to achieve production shooting. And here the enterprise itself shows how everything is done.

And, it should be noted, very successfully.

We filmed on a weekday, and the flow of visitors was simply incredible. In the literal sense, crowds of children and all arriving and arriving buses.

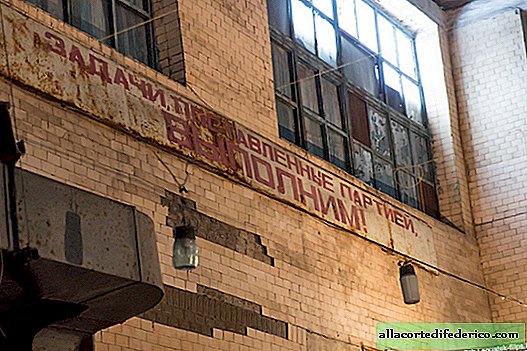

Scoop here, of course, everywhere.

And it is very enticing.

I wonder what party they are working for now)

Glassblowing shop. The workplace is simple: a gas burner, pipes with gas and compressed air, an exhaust chute and a table.

Hell of labor. In the truest sense of the word.

Raw materials for the Christmas tree toys are ... hollow glass tubes.

First they are heated and divided into blanks for balls.

The heated glass begins to melt, becomes plastic and viscous. So the necessary parts of the tube are separated.

Then this elongated fused piece of glass is twisted with a special hook on one side to plug this strange tube on one side.

Surprisingly, these fused pieces of glass still remain hollow inside.

After all, the ball will then be blown out.

Then the workpieces are again heated on the burner to the desired temperature.

In the hand is the future Christmas ball.

And when the glass reaches the desired temperature, the worker simply blows into the tube, blowing the ball.

Glass should be red-hot. Its temperature is about 1000 degrees. The worker has only a few seconds to blow the ball.

Moreover, it should be the right size.

Ball blanks look like a big transparent drop. The leg through which the ball was blown does not break off. It will still be needed on silvering and painting.

For a shift, one worker blows 150-200 balls.

Before sending to the silvering shop.

This is a different building. Here are workshops for silvering, painting and decorating balls.

It is here, in this picturesque place with balls that create real magic - silver them.

It feels like we're in some kind of torture.

This is a needle for injecting a special solution into the ball, which will cover the glass ball from the inside with a thin layer of silver, pure silver.

The solution consists of silver oxide, ammonia, glucose and distilled water.

It is injected quite a bit, then the preform is shaken so that the solution covers the walls inside the ball and lowered for a few seconds into the bath with water heated to 50 degrees, while shaking at the same time.

The silver solution solidifies on the walls of the ball, covering them with the thinnest uniform layer. The process is called the “silver mirror reaction”.

Then the balls fall on the external painting area, where they are covered with one color or another. And then they go to the most interesting site ...

You can’t shoot here, because it distracts workers very much and prevents them from creating magic.

But we were kindly allowed.

Here, the balls are turned into those beautiful Christmas toys that we are used to.

They are painted here.

Coloring of each Christmas tree toy is done manually according to the template.

All the guys who work in this room are graduates of art schools and schools. After all, their task is to make the toys amazing.

They draw in parts. For example, first white snow is applied to the entire batch, then a green tree, then a house, then a window in the house, etc.

Here they make not only balls, but also various three-dimensional toys. For example, such Fushi-Mice. They are also blown, but inside a special form.

After the paint is applied, it is fixed, sprinkled with various materials. This creates the effect of rough snow or volume sparkles.

Can you imagine the painstaking work?

Stand with mockup templates.

Workplace of the artist.

Cutting and packaging site. Here the balls are circumcised - cut off the extra leg.

Well, then the toys go to the store.

In the company store in the factory, a full house.

By the way, children can take a small master class, where they will be taught to paint toys. It's just not easy to get on it - a huge queue is being built.